Inventory Management Services Customized for you!

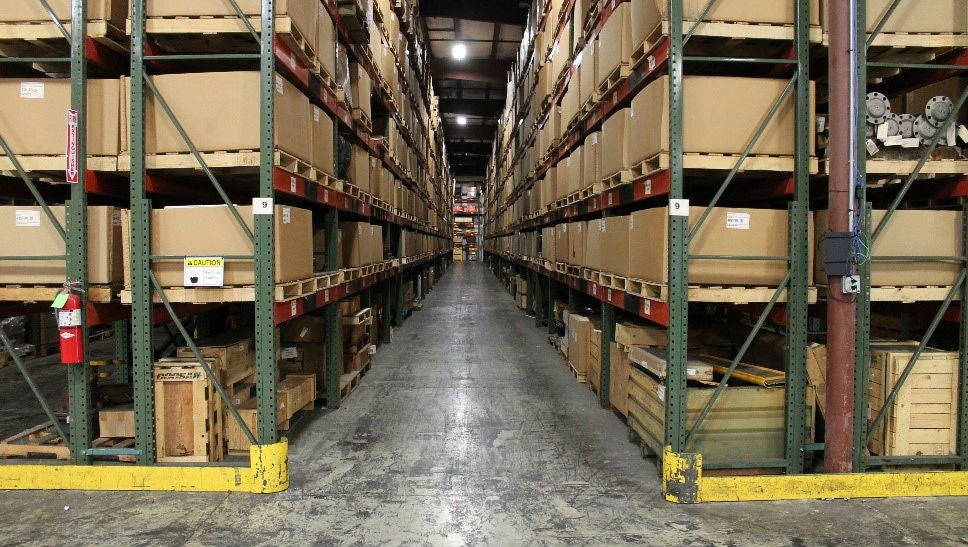

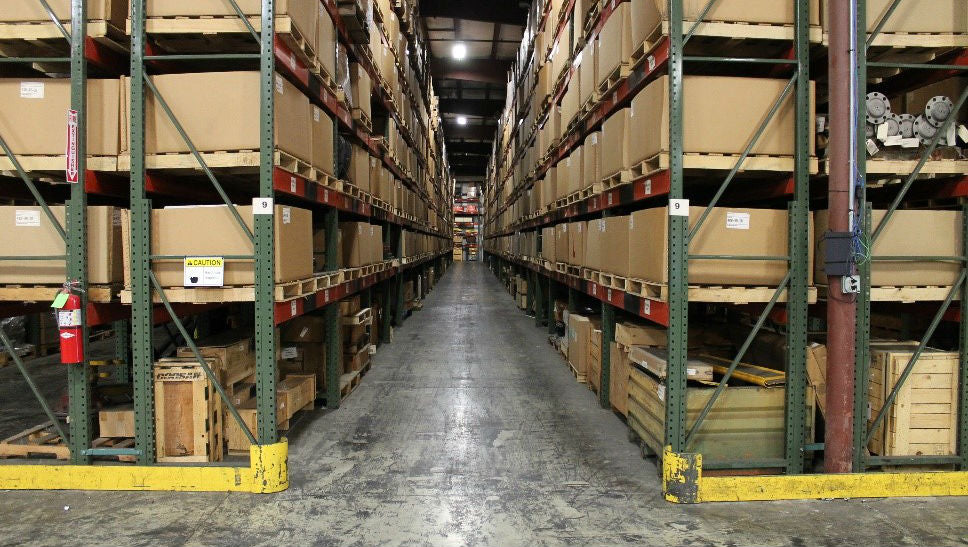

Extending the Life of Inventory

OUR MISSION AND VALUES

Lippert Enterprises extends the life of inventory. This is achieved by offering flexible solutions to our partner networks. Lippert strives to create a sustainable future for our customers, employees, community and shareholders through collaboration, active leadership, continuous improvement and the highest standards of integrity.